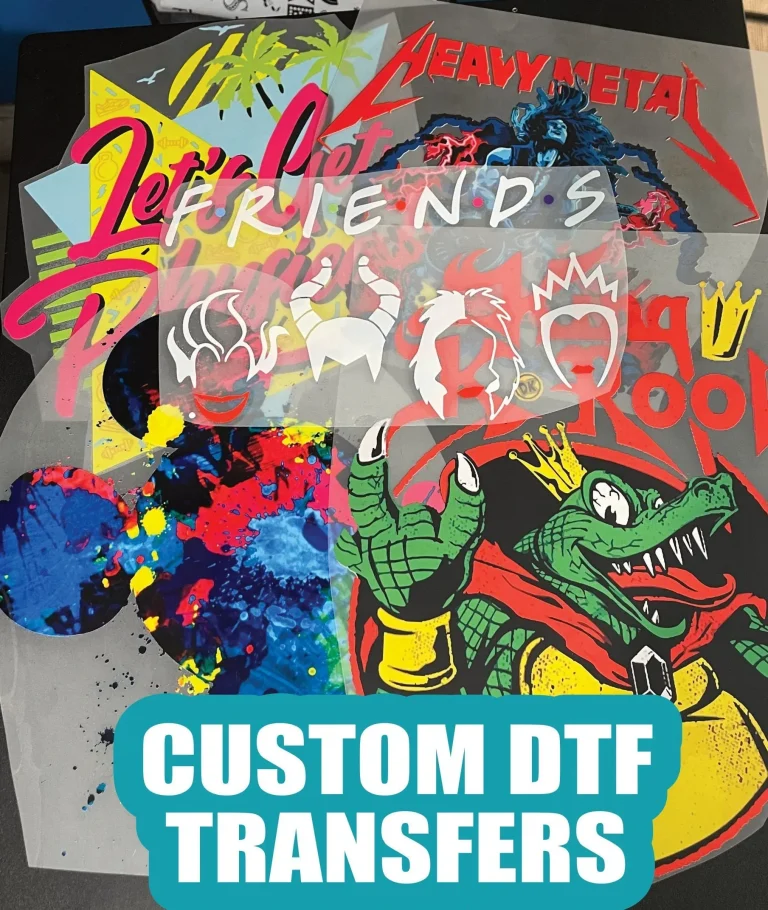

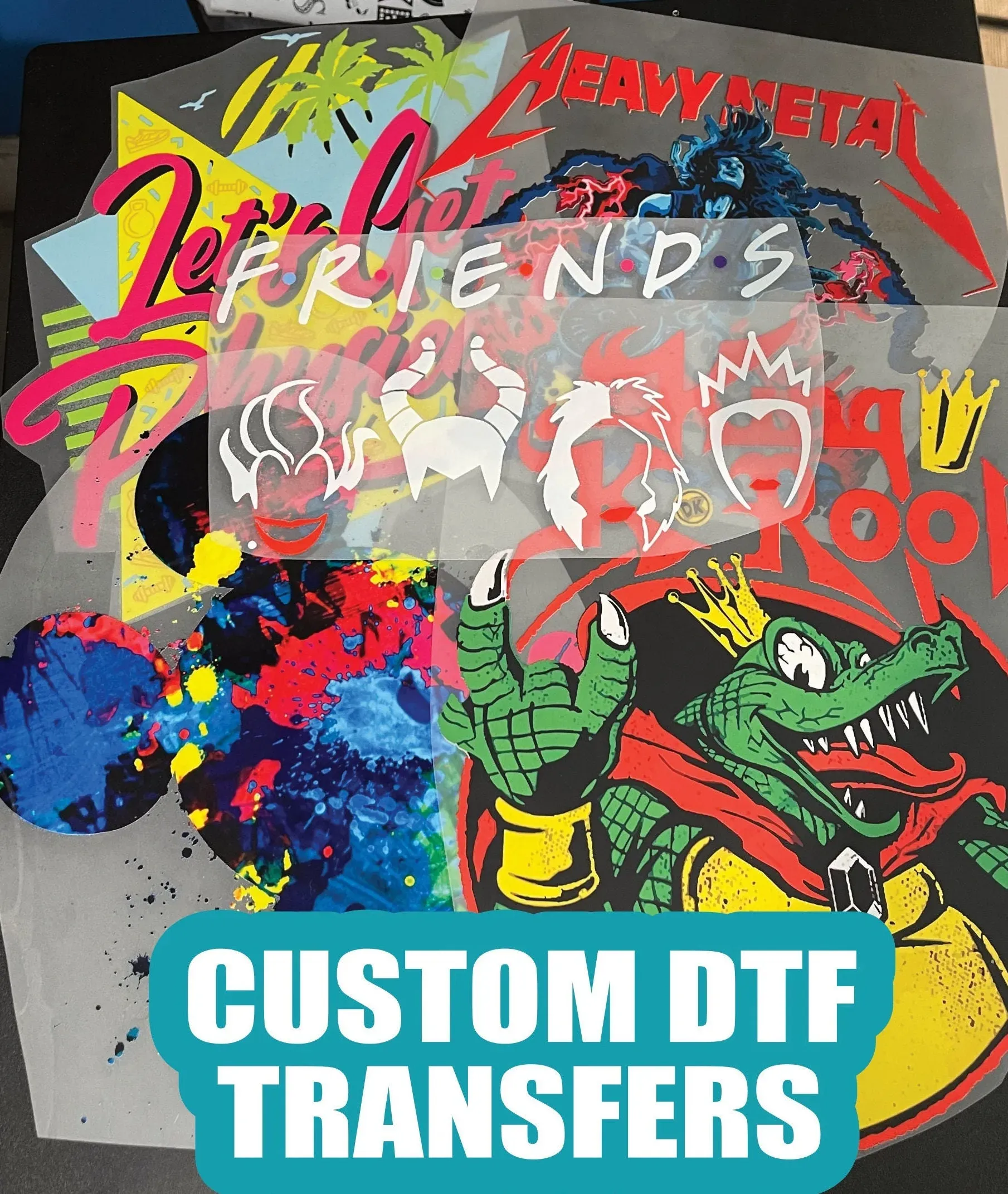

DTF transfers, short for Direct-to-Film transfers, are rapidly gaining popularity among creators seeking to revolutionize their design processes. This innovative printing method allows designers to produce intricate, vibrant designs that can be seamlessly applied to various fabrics, making it a versatile option in the world of custom apparel. With the numerous DTF printing benefits, including the ability to create gang sheets for efficient production, artists can now realize their creative visions with unprecedented ease. Additionally, comparing DTF vs sublimation printing highlights how DTF offers superior capabilities, especially on dark materials that typically pose challenges for other methods. By embracing custom designs with DTF transfers, creators can elevate their artistic expression and produce eye-catching products that stand out in the marketplace.

Direct-to-Film printing presents an exciting frontier for those in the design industry, harnessing modern technology to enhance the fabric printing process. This technique provides an efficient means of transferring detailed graphics onto textiles, ensuring vibrant color reproduction and outstanding resolution. Adopting alternatives like DTF printing can significantly improve production workflows, thanks to advances such as gang sheets that optimize multiple designs simultaneously. Artists, small business owners, and hobbyists alike can benefit from the inherent flexibility of DTF transfers, enabling them to explore new creative possibilities. Ultimately, exploring the world of DTF presents an ideal opportunity to integrate remarkably customizable designs into product offerings.

Understanding the Basics of DTF Transfers

Direct-to-Film (DTF) transfers represent a significant advancement in the printing industry, making custom apparel and product design more accessible to artists and creators. This innovative technology allows for the printing of intricate designs on a special film which, upon heat application, transfers images seamlessly onto various fabrics. Unlike traditional methods such as screen printing, DTF printing offers superior detail and vibrant color reproduction, paving the way for more creative freedom in design.

The DTF process is relatively straightforward, consisting of several pivotal steps. Initially, designers craft their digital art using software, followed by printing the artwork onto specialized DTF film with a dedicated printer. An adhesive powder is then applied to the film, which bonds to the printed ink when heated. Finally, a heat press is used to transfer the design onto the fabric. This method not only enhances quality but also broadens the types of designs that can be executed, making DTF a favorite among contemporary creators.

DTF Printing Benefits: Why Choose This Method?

One of the most compelling advantages of DTF printing is its versatility across various fabric types. Whether you’re working with cotton, polyester, or blends, DTF transfers deliver stunning results on both light and dark materials. This compatibility allows designers to expand their offerings, tailoring products to their target market’s preferences without being constrained by fabric limitations.

Moreover, DTF printing is celebrated for its high-quality output. With the ability to reproduce intricate graphics and maintain excellent color density, artists can confidently create custom designs that stand out. This method is particularly advantageous for those dealing with detailed or multi-colored artworks, as DTF transfers allow for precision and clarity that many traditional printing methods may not achieve.

Maximizing Efficiency with Gang Sheets in DTF

Gang sheets are a game-changing aspect of DTF printing, allowing designers to print multiple designs on a single sheet of film. This approach not only streamlines the production process but also minimizes waste, making it an efficient and cost-effective choice for creators and businesses alike. By grouping designs together, you can save both time and resources, leading to quicker turnaround times and increased profitability.

Furthermore, using gang sheets means that small businesses can efficiently handle diverse orders without requiring extensive equipment or large print runs. For instance, an independent artist can work on limited edition collections by printing multiple designs at once, thus maximizing their production capabilities while keeping costs down. This technique best exemplifies how DTF printing embraces sustainability in the manufacturing process by optimizing material usage.

DTF vs. Sublimation: Choosing the Right Method

In the debate between DTF printing and sublimation, understanding the key differences can empower designers to make informed choices for their projects. DTF technology shines when it comes to printing on a broader range of fabrics, especially dark materials, where sublimation may struggle to effectuate vibrant colors. This unique aspect of DTF printing ensures that no matter the fabric color, your designs can remain impactful and visually striking.

Additionally, DTF offers flexibility in design adaptation compared to sublimation. With DTF, the possibility of adjusting and removing transfers from fabrics without damage enables designers to experiment freely and make creative revisions as needed. This flexibility is crucial in an industry where trends can shift rapidly, allowing artists to stay relevant and responsive to customer demands.

Creating Custom Designs with DTF Transfers

The ability to create custom designs using DTF transfers opens up immeasurable possibilities for creativity in the fashion and merchandise sectors. Designers can harness the technology to produce personalized apparel, unique gifts, or promotional items that reflect individual styles and brand identities. This level of customization not only enhances customer satisfaction but also increases the perceived value of the products offered.

As DTF technology becomes more accessible, artisans, small businesses, and hobbyists can leverage these capabilities to stand out in a crowded marketplace. The key is to focus on high-quality design creation—ensuring that artwork is sharp and vibrant to fully exploit the advantages of DTF printing technology. Whether for entrepreneurial efforts or personal projects, custom designs through DTF are an excellent way to express creativity and cater to specific market needs.

Staying Ahead with DTF Printing Technology Trends

The DTF printing landscape is rapidly evolving, with significant industry trends shaping its future. Recent developments, such as Eazydtf’s substantial investments in advanced printing technology, showcase the increasing demand for high-quality DTF products. These advancements are likely to push the boundaries of what’s possible with DTF printing, enabling even more intricate designs and improving overall service efficiency for customers.

Furthermore, the introduction of consumer-grade DTF printers has made this technology accessible to a broader audience. Small business owners and home-based creators can now explore innovative design opportunities without the need for extensive resources. As the market continues to grow and diversify, staying updated with emerging technologies and trends in DTF printing will prove essential for creators aiming to maintain a competitive edge.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing method that involves printing designs onto a special film, which are then heat-transferred onto various fabrics. The process includes design creation, printing on the film, applying an adhesive, and heat pressing the film onto the desired surface.

What are the key benefits of using DTF printing for custom designs?

DTF printing offers numerous benefits for custom designs, including versatility across various materials, high-quality prints with intricate details, and efficiency through the use of gang sheets. These advantages make DTF an exceptional choice for artists and small businesses.

How does DTF printing compare to sublimation printing?

DTF transfers differ from sublimation printing primarily in versatility. While sublimation requires specific materials (generally light, polyester fabrics), DTF printing works effectively on both light and dark fabrics, providing more options for custom designs.

What are gang sheets in DTF printing, and why are they beneficial?

Gang sheets in DTF printing are sheets that contain multiple designs printed together. This method enhances production efficiency by maximizing material usage, reducing waste, and saving on printing time and costs for designers.

Can beginners easily use DTF transfers in their design projects?

Yes, beginners can easily use DTF transfers thanks to advancements in user-friendly technology, such as consumer-grade DTF printers. These devices are designed to simplify the printing process, making it accessible for individuals with little or no prior experience.

What factors should I consider when investing in a DTF printer for my designs?

When investing in a DTF printer, prioritize quality to achieve vibrant colors and sharp details. Additionally, consider features that enhance usability, such as compatibility with various materials, ease of setup, and support for high-resolution graphics to maximize your design potential.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers are a method that prints designs on special film which is then heat-transferred to fabric. It allows for intricate designs and vibrant colors. |

| Advantages of DTF Transfers | Includes versatility on various fabrics, high quality and detail, efficient gang printing, ease of use for small businesses, and removability for flexibility. |

| Recent Industry Trends | Emerging trends such as Eazydtf’s expansion, the introduction of home printers, and the comparative versatility of DTF over other methods. |

| Tips for Incorporating DTF | Invest in quality equipment, focus on design quality, experiment with gang sheets, stay updated with industry trends, and conduct fabric tests. |

Summary

DTF transfers are revolutionizing the world of custom apparel and product design, allowing creators to express their artistic vision with unprecedented detail and vibrancy. By utilizing DTF transfers, artists and entrepreneurs can tap into a versatile printing method that accommodates a broad range of fabrics and designs. As technology continues to advance, the accessibility of DTF printing grows, making it ideal for small businesses and individual creators looking to enhance their product offerings. Whether aiming for unique designs or custom items, DTF transfers enable creators to transform their concepts into tangible realities, setting a new standard in the design industry.